Bestverkopende producten

Bestverkopende producten

Best verkopende

- Toon alles

- Populair in deze maand

- Meest verlanglijst

- Choose category

- All categories

- Uncategorized

- Bloemen

- Bomen

- Fruit

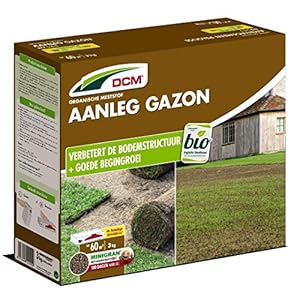

- Gras

- Groente

- Heggen and struiken

- Kruiden

- Vleesetende planten

- Wijnstokken

Added to wishlistRemoved from wishlist 0

Add to compare

Added to wishlistRemoved from wishlist 0

Add to compare

Added to wishlistRemoved from wishlist 0

Add to compare

Added to wishlistRemoved from wishlist 0

Add to compare

Added to wishlistRemoved from wishlist 0

Add to compare

Added to wishlistRemoved from wishlist 0

Add to compare

We volgen de prijzen van meer dan 20 populairste winkels om u de beste deals te geven

Wil je de beste producten kopen

Bekijk de nieuwste aanbiedingen

Added to wishlistRemoved from wishlist 0

€8.28

Added to wishlistRemoved from wishlist 0

€8.28

Added to wishlistRemoved from wishlist 0

€14.99

Lantana Camara Zaden, 100 Stks/zak Lantana Camara Zaden Sunshine Liever Plant in Lente Productieve Onamental Lantana…

Already Sold: 31%

Added to wishlistRemoved from wishlist 0

€1.32

Generic Fresh 50 stks Bromelia Tillandsia Bulbosa plant ZADEN voor het planten van sinaasappel 2

Already Sold: 66%

Added to wishlistRemoved from wishlist 0

€14.99

100 stuks zeldzame chocolade kosmos zaden Cosmos Bipinnatus Calliopsis tuin bloem voor vrouwen, mannen, kinderen…

Already Sold: 60%

Added to wishlistRemoved from wishlist 0

€4.00

Added to wishlistRemoved from wishlist 0

€1.99

Zwaluw Vogel Broche Strass Mooie Broche Broche Dames Kleur Kristal Broche Trui Sjaal Boeket Sieraden

Already Sold: 29%

Added to wishlistRemoved from wishlist 0

€20.88

NOLITOY Model Boom Mini Cactus Planten Trein Landschap Architectuur Bomen Nep Bomen Miniatuur Kunstmatige Boom Nep…

Already Sold: 71%

Added to wishlistRemoved from wishlist 0

€6.19

Added to wishlistRemoved from wishlist 0

€14.99

Added to wishlistRemoved from wishlist 0

€14.99

Added to wishlistRemoved from wishlist 0

€16.85

Dagelijkse aanbiedingen

€69.00

Already Sold: 12

Available: 16

75 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€15.90

Already Sold: 18

Available: 26

69 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€10.03

Already Sold: 21

Available: 31

68 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€1.47

Already Sold: 24

Available: 36

67 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€14.12

Already Sold: 27

Available: 41

66 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€6.93

Already Sold: 30

Available: 46

65 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

€14.99

Already Sold: 33

Available: 51

65 %

Schiet op! Aanbieding loopt binnenkort af

days

0

0

hours

0

0

minutes

0

0

seconds

0

0

U kunt geïnteresseerd zijn

Iets interessants gevonden?

Beste deals onder € 99

- Toon alles

- Populair

- Meest beoordeeld

- Meest gewenst

€1.89

Bavaria’s Groente van het Jaar 2015 ** Ananas Kers 10 zaden ** Super opbrengst en suikerzoet

Already Sold: 98%

Added to wishlistRemoved from wishlist 0

Add to compare

€12.95

Gardenie Gardenia jasminoïdes Kleim’s Hardy – Totale hoogte 25-35 cm – Pot 14 x 14 cm

Already Sold: 30%

Added to wishlistRemoved from wishlist 0

Add to compare

€382.67

YXZQ Outdoor Kunstgras 20mm Stapel Hoge Tuin Synthetische Nep Gras Groen Tapijt Mat Balkon Decoratie

Already Sold: 87%

Added to wishlistRemoved from wishlist 0

Add to compare

Show next

Friday Fabulous Flower – flessenborstel

September 23, 2021

0

Eind juli bloeit er niet al te veel maar deze uitstekende struik bloeit in deze periode. Dit is de bottlebrush buckeye, Aesculus ...

Plant

Wees creatief en kies voor een rode beukenhaag

September 9, 2022

0

Het is een gras, geen paniek…umm

September 23, 2021

0

Lees de nieuwste blogs

Ontdek je favoriete artikel